About us

"Dustr Marianna" LLC was founded in 1997 by Tigran Vardanyan. By introducing modern technologies and equipment, becoming stronger year by year, the company is already one of the leaders in the field of dairy industry and has its own place in the Armenian dairy market.

High-quality raw materials are important for us. We cooperate with the farms of Artik, Karmir, Talin, Aparan, Ashtarak and other regions in terms of milk acquisition and procurement. The milk brought to the factory first of all undergoes chemical and microbiological examination in the company's laboratories. All our laboratories are equipped with modern equipment. If it meets the requirements of the standard, the milk is accepted by the company. The entire production process, from the reception of milk to the distribution of finished products to shops, is under a strict laboratory control. The containers are disposable. Before packaging, they undergo sterilization with specially installed UV lamps.

We have thought about even the smallest details. A special ventilation system is installed in our production building, due to which the air entering the factory undergoes double cleaning, air humidity and temperature are normalized.

Thus, we ensure high sanitary and hygienic standards throughout the production process.

Our factories

The goal of "Dustr Mariana" LLC is to provide the consumer with high-quality food in accordance with all international standards. Since its establishment, our company has been constantly increasing its assortment, simultaneously improving the technologies used. Over time, our factories have been expanded, developed, and the best modern technologies have been implemented.

At the moment, our company has six technically equipped production areas:

- Pasteurized and ultra-pasteurized milk

- Sour dairy

- Cheese

- Dry milk, butter and milk oil

- Curd and curd products

- Ice cream

Our professionals

We highly appreciate the correct selection and training of specialists, therefore we cooperate with the Agrarian University of Armenia and a number of other specialized universities, preparing employees with the necessary qualities.

We also emphasize professional growth, so all our employees are regularly trained. As a result, we have more qualified specialists and higher quality products. The entire work process is under strict control.

Production process

The milk brought to the factory first of all undergoes chemical and microbiological examination in the company's laboratories. All our laboratories are equipped with modern equipment. If it meets the requirements of the standard, the milk is accepted by the company. The entire production process, from the reception of milk to the distribution of finished products to shops, is under a strict laboratory control. The containers are disposable. Before packaging, they undergo sterilization with specially installed UV lamps.

We have thought about even the smallest details. A special ventilation system is installed in our production building, due to which the air entering the factory undergoes double cleaning, air humidity and temperature are normalized. Thus, we ensure high sanitary and hygienic standards throughout the production process.

“Dustr Marianna” LLC has a global management system that includes a quality management system with the requirements of the international standard ISO 9001-2000, an environmental management system with the requirements of the international standard ISO 14001-2004, risk management in the food industry and a HACCP system guaranteed by the Commission Codex Alimentarius.

Key to success

All production units of our company are equipped with the latest equipment and technology, and as a result work productivity has increased. Most of the equipment is imported from Germany and Italy, corresponding to high quality and beautiful design. The company has automatic flow lines that enable saving fuel and electricity. About 90% of the company's production process is mechanized.

A wide range of lactic sour products and cheese produced by our company are presented on the market under the brands "Marianna" and "Bifido". Thanks to the regularly implemented investments and efficient distribution of funds, as well as the improvement of production processes, the Company's products are distinguished by stable high quality features. The company's development was greatly contributed by the start of dry milk and butter productions, which have been operating since 2009. ISO 22000 quality management and food safety standard has been implemented in the company in order to ensure high quality and safety.

Export

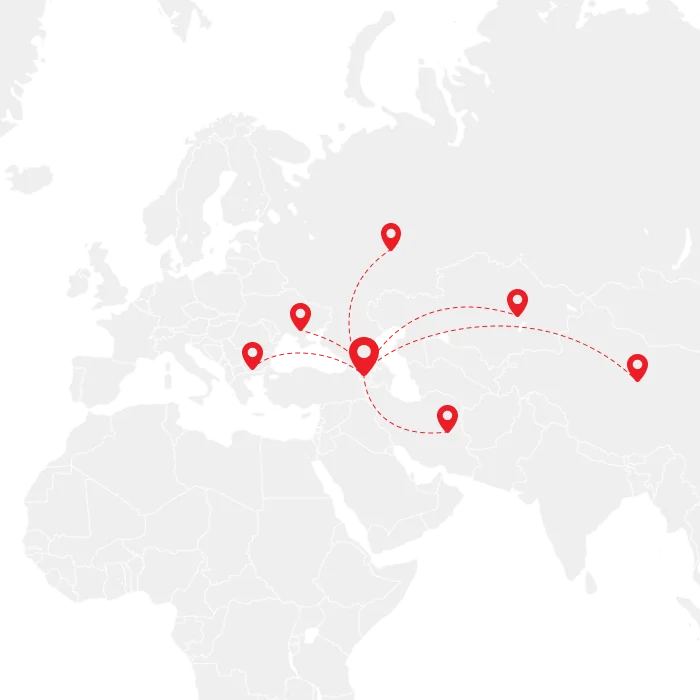

In 2013, our company started exporting products for the first time, initially we entered the Russian market in small volumes. The first products exported were our range of cheeses. The feedbacks were positive, so our company decided to continue and increase the export volumes. Already in 2017, the Company was exporting large volumes of dairy products and ice cream to the Russian Federation. The product is approved by consumers and loved by them. Exports of dairy products and ice cream are also carried out to Georgia.

We also had exports to other countries: USA, Bahrain. The feedback has been positive. Our goal is to expand export borders and increase volumes in the near future.